Overview

Controller specific functions.

This module defines all labbCAN controller specific functions, identifiers and data types for control of measurement and control devices attached to the labbCAN bus. Controller modules are used for closed loop control like heating, cooling or something else. The control is performed by an internal control algorithm like PID or Fuzzy control. The labbCAN controller module offers a device independent API for access to all supported labbCAN measurement and control devices.

- See also

- See Controller Library for a detailed introduction and general overview of controller library.

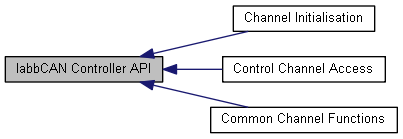

Collaboration diagram for labbCAN Controller API:

Collaboration diagram for labbCAN Controller API:Modules | |

| Channel Initialisation | |

| Controller module channel initialisation functions This group defines all functions to initialise controller channels properly. | |

| Common Channel Functions | |

| Common channel specific auxiliary functions. | |

| Control Channel Access | |

| Control channel access functions This group defines all functions for access to control parameters like setpoint or actual value. | |

Enumerations | |

| enum | LoopOutType { ANALOG, DIGITAL, DIGITAL_PWM, PUMP_FLOW } |

| Control loop output type This enumeration defines the output types for dynamic control channels. More... | |

| enum | PIDParameterId { PID_PARAM_K = 0, PID_PARAM_T_I, PID_PARAM_T_D, PID_PARAM_DERIVATIVE_GAIN_LIMIT, PID_PARAM_T_T, PID_PARAM_MAX_U, PID_PARAM_MIN_U, PID_PARAM_DISABLED_U, PID_PARAM_INITIAL_SETPOINT, PID_PARAM_SAMPLE_TIME, PID_PARAM_COUNT } |

| ID parameter identifier Identifier for all PID control loop parameter that can be changed via LCC_SetPIDParameter. More... | |

Enumeration Type Documentation

| enum LoopOutType |

Control loop output type This enumeration defines the output types for dynamic control channels.

- See also

- LCC_CreatePIDControlChannel

| enum PIDParameterId |

ID parameter identifier Identifier for all PID control loop parameter that can be changed via LCC_SetPIDParameter.

Before your can use a control loop, you should properly set all control loop parameters. You can use the QmixElements software for PID parameter testing and PID tuning.

- See also

- LCC_CreatePIDControlChannel